OXYGEN & NITROGEN GENERATORS

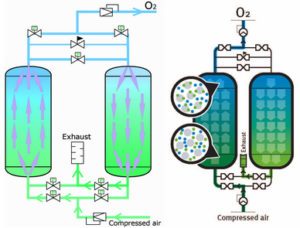

We are authorized sales and service partner of Oxymat A/S in Nepal. Oxymat is a Danish based company is specialized in designing and manufacturing of on-site medical oxygen generators using Pressure Swing Adsorption (PSA) technology. They have been manufacturing oxygen generators since 1978 and they posses first-hand knowledge of the market, developments, demands and possibilities that PSA technology holds.

They are headquartered just north of Copenhagen, Denmark and have several employees working in manufacturing locations in Denmark and Slovakia. Oxymat customers are global and they have strong service back-up. Oxymat standard generator systems are available in nearly several standard models, and they cover oxygen flowrates from 0,6 to 322 m³/hr.

Download our product profile to access offline.